Paint Booth for valves

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category.

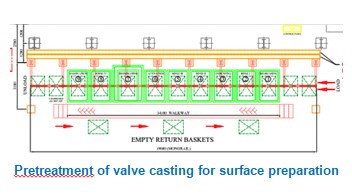

Paint booth for valves � Autocoat Engineering has a vast experience in the field of pretreatment for valves. For valve painting we have devised different paint booths depending on the size & weights of the valves . Most important is the process flow while developing any painting line for the valves or any casting products. Quality improvement can easily be achieved once the process is set. Spray Painting process in a valve paint booth - The specification covers surface preparation and application of protective coating on valves. Paints have excellent resistance to various chemicals. Unpainted surfaces The following surfaces will not require protective coating. Unpainted areas eg Anodized Aluminum Grounding Pads Brass Machined Surfaces Bronze valves Leads Chromium Plated Metals Porcelain Enamel Finishes Copper Rubber Galvanized Steel Stainless Steel Glass. Stage 1 - Pre-treatment of valve casting before sending to paint booth for valves. As soon as casting are checked and ok for further process, Surface cleaning of the valve casting to be carried out. A minimum of 7 tank process or 10 tank process is necessary for the pre-treatment of valve casting . For more information Contact Us. Once a phosphate coat is applied , valve cast is transferred to motor paint booth . This process can even be carried out by Shot Blasting Method. Once phosphate coat is applied primer painting of valve to be done , within shortest time ,to avoid oxidation of the valve castings.

Stage 2 � Valve painting � As shown above valve castings are singularly placed over

a jig or a pattern of jig where multiple valve casting can be painted with primer or

red oxide in the valve paint booth.

With jigs at use and right spray booth desired paint film in microns is achieved. Due

to paint booth undesired over sprays are removed from the painting area , thereby

making a smooth finish over the valve cast. Primer painting gives a corrosion

resistance & also enhances other visual defects can be monitored after the final

assembly ,before the final coat been applied.

Stage 3 � Application of primer for additional coat building & surface cleaning before final finish coat can be applied.

During the assembly of the valves, the valve passes through many component assembly areas, testing zones etc . During this lot of oil & grease marks get over the cast. These marks are to be removed thoroughly with cleaners and again a mid primer coat is applied in the valve spray booth. At this stage putty application is to be applied to remove undesired pin holes & damages on the valve body .

Stage 2 � Valve painting � As shown above valve castings are singularly placed over

a jig or a pattern of jig where multiple valve casting can be painted with primer or

red oxide in the valve paint booth.

With jigs at use and right spray booth desired paint film in microns is achieved. Due

to paint booth undesired over sprays are removed from the painting area , thereby

making a smooth finish over the valve cast. Primer painting gives a corrosion

resistance & also enhances other visual defects can be monitored after the final

assembly ,before the final coat been applied.

Stage 3 � Application of primer for additional coat building & surface cleaning before final finish coat can be applied.

During the assembly of the valves, the valve passes through many component assembly areas, testing zones etc . During this lot of oil & grease marks get over the cast. These marks are to be removed thoroughly with cleaners and again a mid primer coat is applied in the valve spray booth. At this stage putty application is to be applied to remove undesired pin holes & damages on the valve body .

Stage 4 � Application of final finish colour for valve painting � After the above stage the assembled motors are either dried on conveyor for valve painting or by other batch process. The valvess are finally painted by two methods for smaller sizes Conveyorised valve painting method & for Large n heavy valves - Paint booth for valves with material handling equipment.

Autocoat has supplied many motor paint booths & conveyorised motor painting lines, which are running almost in 3 shift basis trouble free. We have designed, developed & manufactured Conveyor motor painting for frame sizes from (83 to 132 ) . Conveyorised motor painting is very fast & economical.

Stage 4 � Application of final finish colour for valve painting � After the above stage the assembled motors are either dried on conveyor for valve painting or by other batch process. The valvess are finally painted by two methods for smaller sizes Conveyorised valve painting method & for Large n heavy valves - Paint booth for valves with material handling equipment.

Autocoat has supplied many motor paint booths & conveyorised motor painting lines, which are running almost in 3 shift basis trouble free. We have designed, developed & manufactured Conveyor motor painting for frame sizes from (83 to 132 ) . Conveyorised motor painting is very fast & economical.

We have also developed, Industrial Valve painting with monorail handling equipment for heavy valves, this method enhances the capability of the painter to lift & lower the heavy valves & also to rotate . Our valve spray booths are very efficient & match the pollution board norms.

Training sessions are been conducted to educate the painters & subordinates to get maximum productivity & effective maintenance.

Our major clients from motor industry are Inditec valves , Fainger valves , M&F valves , & many more.

We have also developed, Industrial Valve painting with monorail handling equipment for heavy valves, this method enhances the capability of the painter to lift & lower the heavy valves & also to rotate . Our valve spray booths are very efficient & match the pollution board norms.

Training sessions are been conducted to educate the painters & subordinates to get maximum productivity & effective maintenance.

Our major clients from motor industry are Inditec valves , Fainger valves , M&F valves , & many more.